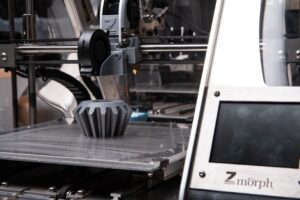

Envision a creative journey with endless prospects. That’s what 3D printing offers – a space where raw materials can become real objects of incredible complexity. But, like any journey, there may be bumps. Here, we’ll discuss some frequent problems in 3D printing and provide solutions so you can get the most out of this remarkable tech.

Start by understanding the basics of 3D printing. Learn the varying types of 3D printers and their features. From filament-based to resin-based, each has its own benefits and drawbacks. Also, know the software used for designing and slicing models. This knowledge will be essential as we go on.

Many 3D printing enthusiasts struggle with poor bed adhesion. This causes warped or misaligned prints. To avoid this, make sure your print bed is level and clean. You can also use glue or hairspray for enhanced adhesion. Taking these steps can boost your prints’ success rate.

Here’s an example of troubleshooting in 3D printing. A friend started a 3D printing project but got visible layer lines. He adjusted the temperature and reduced print speed. Through trial and error, he got smooth prints.

Common Issues in 3D Printing

3D printing has become a popular way of manufacturing in various industries, but it comes with its own set of issues. Let us explore some of the usual problems and how to overcome them.

- Print Quality: Poor quality prints are common issues with 3D printing. It may be caused by wrong printer settings, bad support structures, or inconsistent filament. To solve this, make sure you calibrate your printer properly, use the right support structures, and buy high-quality filaments.

- Warping: Warping is when printed parts curl/bend due to uneven cooling. This happens when the bed is too hot compared to the environment. To prevent warping, use a heated bed, add adhesive materials like painter’s tape, and consider enclosing the 3D printer.

- Clogging: Clogging of the nozzle can disrupt printing. This is due to debris or filament buildup. To prevent clogging, do regular maintenance and cleaning of the nozzle. Also, use good filaments with even diameter.

- Layer Adhesion: Insufficient adhesion between layers can lead to weak parts. This is usually caused by improper extruder temperature or weak bed adhesion. To improve layer adhesion, set the extruder temperature correctly, adjust bed leveling, and use adhesives.

- Stringing: Stringing happens when thin strands of filament appear between objects. It is caused by too much oozing from the nozzle during non-print moves. To reduce stringing, adjust retraction settings, increase travel speed, and enable features like “coast” or “wipe”.

- Support Removal: Removing supports can be tricky for intricate prints. Use slicing software that generates removable supports. Use dissolvable supports if your printer supports them. After that, use post-processing techniques such as sanding or cutting tools.

Each case may have its own details. To troubleshoot any unexpected problems, understand your printer model and materials.

Historically, 3D printing was emerging and resources were limited. People used to struggle to find reliable troubleshooting guides. But, as 3D printing became popular, communities formed online and exchanged knowledge through forums. This helped individuals overcome 3D printing problems.

Solutions for Clogged Nozzle

Nozzle clogs can be a real hassle when using 3D printing. But no need to worry – here’s a 5-step guide to help you get your printer up and running again!

| Step | Instructions |

|---|---|

| 1 | Heat up the nozzle on your 3D printer. This will soften any material causing the clog. |

| 2 | Carefully remove the filament from the extruder. Don’t use too much force! |

| 3 | Use a small wire brush or needle to clean out any debris blocking the nozzle. |

| 4 | If the residue is stubborn, try a 3D printing filament cleaner. Follow the instructions provided. |

| 5 | Reinsert the filament and run a test print. Make adjustments to temperature and print settings if needed. |

Remember – every 3D printer is unique. If these steps don’t help, consult your manual or seek professional help. Maintaining and cleaning your nozzle regularly can prevent clogs in the future. Get back to making your 3D printing projects – your next masterpiece awaits!

Solutions for Layer Shifting

Layer shifting is a common problem with 3D printing, resulting in misaligned and distorted prints. Don’t despair – there are ways to fix it! Follow this 3-step guide for smooth and accurate layers in your 3D prints.

| Step | Solution |

|---|---|

| 1. | Check belt tension: Take a look at the 3D printer’s belts. Loose belts can cause layer shifting. Make sure they are tight and aligned. |

| 2. | Verify stepper motor connections: Check the connections of the stepper motors. Loose or faulty connections can lead to layer shifting. Ensure that cables are plugged in securely. |

| 3. | Adjust print speed and acceleration: Changing the print speed and acceleration settings also helps prevent layer shifting. High speeds or sudden changes in acceleration can stress the printer’s components, resulting in layer errors. Try lower speeds and gradual acceleration to find the best settings for your printer. |

In addition, maintain a stable environment for your printer. Avoid vibrations and other disturbances.

Pro Tip: Regularly calibrate your printer with test prints like the “XYZ calibration cube” or “benchy.” This will help identify any layer shifting issues and let you fine-tune settings for better results.

Follow these solutions and do proper maintenance. Now you’re ready to tackle layer shifting and get great prints every time!

Solutions for Warping

- Use a heated bed. It maintains an optimal temperature, preventing warping.

- Apply adhesive materials, like hairspray or glue, to enhance adhesion and reduce warping.

- Adjust printing settings such as nozzle temperature, print speed, and cooling.

- Use a brim or raft for extra support at the base and minimize warping.

- Increase infill density for better internal structure and reduce stress on the print.

- Use an enclosure to maintain a consistent ambient temperature and prevent sudden changes which can lead to warping.

Also, store filaments properly in an airtight container with silica gel packs to avoid absorption of moisture which can cause warping.

MIT researchers have developed a “layer-free” printing technique which eliminates common issues like layer separation and warping during the printing process (Source: MIT News).

Fascinating!

Conclusion

Our troubleshooting journey in 3D printing ends with a feeling of success. We now have the knowledge and strategies to face any challenge and turn our ideas into reality. Though the tech keeps evolving, the right solutions give us success.

Before we leave this article, it’s good to point out some details that’ll help us get perfect prints. Leveling the print bed, high-quality filament, and great printing temps are important. These little things can make a huge difference.

As we explore 3D printing troubleshooting more, we learn about a group of innovators. Despite their repeated failures, they never gave up. They used each challenge as a learning opportunity. This gave them problem-solving skills that make 3D printing easier around the world.

Frequently Asked Questions

1. Why is my 3D printer not extruding filament properly?

There could be several reasons for this issue. First, check if the nozzle is clogged with debris or filament. Clean the nozzle or replace it if necessary. Secondly, make sure the filament is loaded correctly and that there are no knots or tangles in the spool. Finally, check the temperature settings to ensure it is suitable for the filament being used.

2. What should I do if my 3D printed object has gaps or holes?

Gaps or holes in a 3D printed object are typically caused by under-extrusion. Ensure that the filament diameter is set correctly in the slicing software. Additionally, check the tension of the extruder’s filament drive gear and adjust it if needed. Increasing the printing temperature can also help in some cases.

3. Why is my 3D printer making a grinding noise?

A grinding noise usually indicates an issue with the extruder gear skipping or slipping against the filament. This can occur if the filament is not properly inserted or if the nozzle is partially clogged. Check for any obstructions in the extruder assembly, clean the nozzle, and ensure that the filament is properly fed into the printer.

4. What should I do if my 3D printer’s prints are coming out with rough surfaces?

Rough surfaces on 3D prints can be caused by several factors. Firstly, check the print bed leveling and adjust it if necessary. Ensure the nozzle is at the correct height from the bed. If the roughness persists, try reducing the printing speed or increasing the layer thickness. It’s also important to use the right type of filament for the desired finish.

5. Why is my 3D printer displaying errors during the printing process?

Errors during printing can indicate various issues. Make sure to update the firmware and software of your 3D printer to the latest version. Check the connection between the printer and computer or ensure that the SD card is properly inserted. If the error persists, consult the printer’s user manual or contact the manufacturer for assistance.

6. What should I do if my 3D printer’s print quality is inconsistent?

Inconsistent print quality can be caused by a few factors. Check the extruder assembly and make sure it is clean and free from any residual filament. Adjust the extrusion multiplier in the slicing software to fine-tune the flow of filament. Additionally, ensure that there are no loose belts, and calibrate the printer’s stepper motor drivers if necessary.