3D printing tech has changed the manufacturing industry. This article looks at the potential of 3D printing and offers tutorials to get started.

It’s clear 3D printing is here to stay. It can make production faster, easier and more cost-effective. There are tutorials to suit every industry – from automotive to aerospace. They cover everything from designing to material usage.

The great thing about these tutorials is that they go beyond the basics. They explore complex problems where traditional methods don’t work. This makes them invaluable for niche industries.

Remember, it’s also important to be creative. Innovation comes from stepping away from the norm and trying something new.

Industry-specific 3D printing tutorials are paving the way for a new future of manufacturing. As technology advances, they’ll help makers keep up and unlock exciting possibilities.

What is Industry-Specific 3D Printing?

Industry-Specific 3D Printing is a revolutionary tech that’s changing manufacturing. It works by adding layers of material through a computer-controlled process, to create 3D objects. Unlike traditional methods, this printing caters to specialized needs of sectors like aerospace, healthcare and automotive.

Versatility of this printing allows for intricate and customized designs. In the aerospace industry, 3D printing creates lightweight parts that meet strict performance demands. In healthcare, it enables personalized medical implants that fit individuals’ anatomical structures.

It also streamlines manufacturing processes, reducing waste and cost. With 3D printing, only the necessary material is used, cutting out excess. This minimizes wastage and lowers production costs.

As an example, GE utilized this tech to make jet engine parts for their GE90 engines – one of the world’s most powerful. By introducing 3D printing, they achieved impressive results – 25% lighter and less fuel consumption while keeping performance. This highlights how 3D printing can enhance productivity and efficiency across industries.

Benefits of Industry-Specific 3D Printing

Industry-Specific 3D Printing offers lots of advantages that suit different industries. It allows for exact customizing and increased productivity, changing the way production is done.

Advantages of Industry-Specific 3D Printing are:

| Benefits | Description |

|---|---|

| Enhanced Customization | 3D printing helps make unique products, with highly specific designs. |

| Cost Reduction | By cutting back on material waste and tooling costs, the expenses are much lower. |

| Faster Prototyping | With rapid prototype production, product development is speeded up. |

| Improved Product Quality | Using 3D printing technology brings higher quality end products, with consistent standards. |

| Supply Chain Flexibility | Not needing external suppliers boosts production flexibility. |

| Increased Innovation | It encourages creativity, making it possible to explore new design ideas. |

Also, industry-specific 3D printing has the ability to incorporate many materials and complex shapes into production simply.

Pro Tip: When you use industry-specific 3D printing, give your staff proper training to get the most out of it and improve the results.

Challenges and Limitations of Industry-Specific 3D Printing

Industry-specific 3D printing comes with its own set of issues. These barriers keep the tech from reaching its full potential in several sectors. Let’s explore the challenges that must be conquered for successful implementation.

The table below shows some of the key challenges and limitations faced by industry-specific 3D printing:

| Challenge/Limitation | Description |

|---|---|

| Complex Designs | Making intricate models can take a long time and needs advanced skills. |

| Material Limitations | Certain materials may not work with 3D printing, limiting the options. |

| Production Speed | 3D printers are slower than traditional manufacturing methods. |

| Cost | Purchasing or leasing equipment can be expensive, discouraging small businesses. |

| Quality Control | Testing and calibration must be done to ensure consistent quality. |

Apart from these challenges, industry-specific 3D printing also has unique limitations. But, tech advancements and research could help to overcome these issues.

For industry-specific 3D printing to reach its true potential, experts from different fields need to work together. With collaboration, engineers, designers, material scientists, and manufacturers can come up with new solutions.

This tech holds great possibilities for multiple industries. Businesses must stay ahead by leveraging industry-specific 3D printing. Not doing so could mean missing out on growth and competitiveness.

Getting Started with Industry-Specific 3D Printing

Ready to get started with industry-specific 3D printing? Here’s a 3-step guide!

- Explore Applications: Look into how 3D printing can change processes in your sector. It can be healthcare, aerospace, automotive, or fashion. Each has different needs that 3D printing can meet.

- Choose Right Tech: Once you know the application, pick the right 3D printing tech. Options include SLA, SLS, FDM, and DLP. Pick the one that suits your needs best.

- Master Design: Learn how to design for additive manufacturing. It’s different from subtractive manufacturing. Understand concepts like support structures, overhangs, and tolerances to optimize designs. Also, think about material selection, post-processing, and quality control.

In recent years, 3D printing has revolutionized whole sectors. For example, 3D printed prosthetics in the medical field have changed lives by providing customizable solutions at an affordable cost.

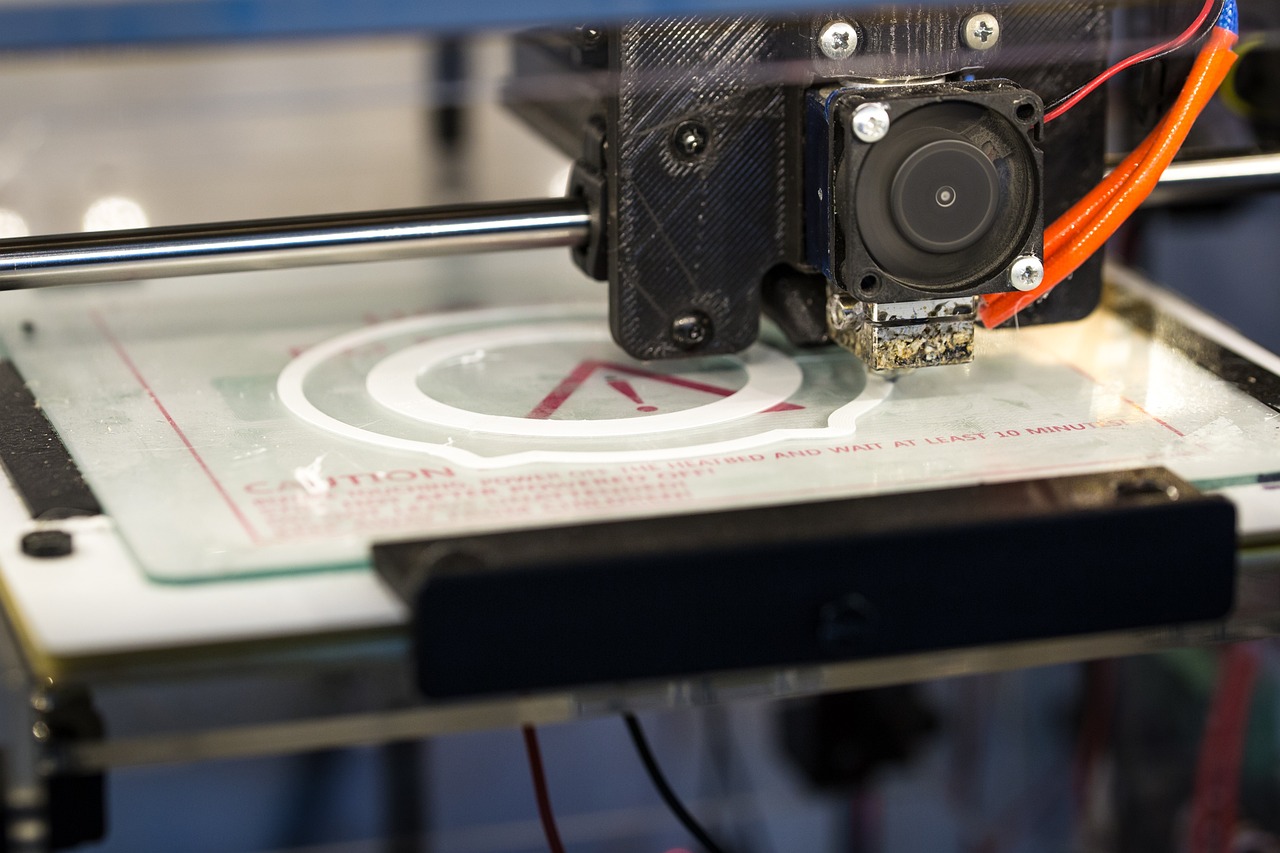

Step-by-Step 3D Printing Process for Industry-Specific Applications

3D printing for industry-specific applications takes various steps to make accurate, functional objects. By using a step-by-step guide, people can navigate the intricate process without a hitch.

- Step 1: Designing the Object. Create a digital design of the object using special software. This design serves as the 3D printer’s blueprint, providing all needed specs and dimensions.

- Step 2: Preparing the Printer. Upload the design to the 3D printer. Before starting the printing, check that it’s calibrated correctly and that all materials and settings are ready.

- Step 3: Material Selection. Choose the appropriate material for the application. Different industries need different materials with specific characteristics such as strength, flexibility, or heat resistance to make sure the finished product works as intended.

- Step 4: Printing Process. Then, begin the printing process. The 3D printer will layer thin slices of material as per the design’s specs, building a 3D object from scratch.

- Step 5: Post-Processing. After printing, post-processing may be needed to achieve the desired finish. This may include removing support structures, sanding rough surfaces, or adding coatings for durability or aesthetics.

- Step 6: Quality Control. Last, do quality control checks to make sure the printed object meets all requirements and specs before use.

These steps are general guidelines. Each industry may have its own nuances and additional steps specific to their applications. Therefore, it’s important to understand these and adjust each step accordingly for the best results.

3D printing has come a long way since its beginning in the 1980s. It was mainly used for rapid prototyping then. Now, technology and materials have widened its applications to aerospace, automotive, healthcare, and consumer goods. The ongoing 3D printing evolution has enabled industry-specific tutorials so people can learn the step-by-step process to make objects suited to their specialized needs.

Post-Processing and Finishing Techniques for Industry-Specific 3D Prints

Post-processing and finishing techniques are key to creating top quality, industry-specific 3D prints. These steps refine the prints and make them look and work better. If you use these techniques, you can make sure your 3D prints meet the industry’s needs.

To help you get an idea of post-processing and finishing techniques for industry-specific 3D prints, we made a table. It has columns like cleaning, sanding, painting, and polishing. Along with this, there is a brief description for each step. This guide will help you make great 3D prints.

| Technique | Description |

|---|---|

| Cleaning | Removal of support structures and extra material using solvents or mechanical methods |

| Sanding | Smoothing out rough surfaces or imperfections with different grits of sandpaper |

| Painting | Applying paint or coatings to improve the look of the printed object |

| Polishing | Buffing or smoothing the surface using abrasives to get a glossy finish |

| Assembly | Joining multiple printed parts together to make a functional product |

Apart from these common techniques, there are unique ones used in some industries. For example, heat treatment or electroplating can be done to improve strength or corrosion resistance. Consider these industry-specific needs when planning your post-processing approach for 3D prints.

Business Wire found in a study that the global market for 3D printing in manufacturing is projected to reach $56 billion by 2024. This shows the potential of this technology to revolutionize traditional manufacturing processes.

Case Studies: Successful Applications of Industry-Specific 3D Printing

The realm of 3D printing has been harnessed by numerous industries, with great success. Let’s look at some case studies that demonstrate its impactful industry-specific applications.

The following table offers an insight into the fruitful outcomes of 3D printing in various industries:

| Industry | Case Study | Impact |

|---|---|---|

| Automotive | Ford Motor Company use 3D printing for car part prototyping. This leads to quicker design iterations and cost savings. | Decreased production time and cost, improved product quality. |

| Aerospace | Boeing employ 3D printed components for their aircraft, resulting in lighter weight and improved fuel efficiency. | Better fuel efficiency, decreased environmental impact. |

| Healthcare | Medical institutions incorporate 3D printing to make customized prosthetics and implants that fit the patient’s anatomy. | Improved patient outcomes, increased comfort. |

| Architecture & Construction | Architects use large-scale 3D printing for complex building structures with intricate designs. This reduces manual labor and construction time. | More design freedom, faster construction process. |

These case studies emphasize the widespread use of industry-specific 3D printing across many sectors.

Although this article focuses mainly on successful applications, there are still challenges in terms of optimizing material properties and scaling production capabilities.

According to a SmarTech Analysis report from May 2021, the global market for additive manufacturing materials is expected to reach $2 billion by 2025.

Future Developments and Trends in Industry-Specific 3D Printing

The future of 3D printing in industry-specific applications is set for stimulating progress and tendencies. From healthcare to automotive, this technology is transforming manufacturing methods. Let’s investigate some of the major advances and potentials.

To more accurately comprehend the future of industry-specific 3D printing, let’s inspect the following characteristics:

| Industry | Development/Trend |

|---|---|

| Healthcare | Tailor-made medical implants and prosthetics |

| Automotive | Additive fabrication for speedy prototyping |

| Aerospace | Lightweight elements for augmented fuel efficiency |

| Fashion | Exceptional and personalized designs on-demand |

| Construction | 3D printed constructions and infrastructure |

In addition to these developments, another thrilling area of growth is the investigation of advanced materials for 3D printing. Experts are trying out new combinations and compositions that offer advanced features like durability, flexibility, and conductivity. This opens up possibilities for even more assorted applications across diverse industries.

As industries keep on embracing 3D printing technologies, it becomes necessary to take into account apprehensions regarding intellectual property rights and quality control. Regulations and regulations will be a crucial part in making sure the dependability and safety of 3D printed products.

Pro Tip: Stay up-to-date with the latest advancements in particular industries to unlock one-of-a-kind possibilities for utilizing 3D printing technologies effectively.

Conclusion

Today, 3D printing is transforming the manufacturing industry. It’s providing efficient and cost-effective solutions for automotive, aerospace, and healthcare sectors. As technology advances, industry-specific 3D printing tutorials are a valuable resource for businesses wanting to use this groundbreaking technology.

These tutorials give step-by-step instructions on how to use 3D printing in a specific industry, tackling unique challenges and needs. They provide detailed guidance and best practices, empowering manufacturers with the knowledge they need to improve their production processes.

Tutorials cover various topics like material selection, design considerations, machine calibration, and post-processing techniques. Each one focuses on the needs of a sector, ensuring manufacturers make informed decisions throughout the 3D printing workflow.

By following these tutorials, manufacturers can unlock new opportunities for innovation and customization. In the automotive industry, for example, tutorials explore how 3D printing can be used to build lightweight parts with complex geometries for better performance and fuel efficiency. Healthcare-specific tutorials look at biofabrication techniques for creating patient-specific implants or prosthetics.

A pro tip when using industry-specific 3D printing tutorials is to adapt them to your requirements. These resources give invaluable insights and guidelines, but it’s important to think about your organization’s objectives and constraints. Tailoring them to your needs will make sure you’re getting the most out of 3D printing technologies.

As 3D printing advancements shape the future of manufacturing, industry-specific tutorials will become even more important in helping businesses streamline their production processes across sectors. Using this educational resource will not only increase operational efficiencies but also promote innovation and growth in today’s rapidly changing manufacturing landscape.

Frequently Asked Questions

1. What is industry-specific 3D printing?

Industry-specific 3D printing refers to the use of 3D printing technology in specific sectors such as automotive, healthcare, aerospace, or consumer goods. It involves creating customized products, parts, or prototypes using additive manufacturing techniques.

2. How does industry-specific 3D printing benefit manufacturing?

Industry-specific 3D printing offers several benefits to the manufacturing sector. It enables faster production times, reduces costs by eliminating the need for traditional tooling, allows for complex designs, and supports customization and personalization of products.

3. What are some industry-specific 3D printing tutorials available?

There are various industry-specific 3D printing tutorials available, depending on the sector. Some examples include tutorials on 3D printing automotive parts, medical device prototypes, aerospace components, or household products.

4. Can beginners without prior 3D printing experience benefit from these tutorials?

Yes, industry-specific 3D printing tutorials cater to beginners as well as those with advanced knowledge. They often provide step-by-step instructions, tips, and resources to help individuals get started with 3D printing in a specific industry.

5. Are there any software requirements for industry-specific 3D printing?

Yes, industry-specific 3D printing tutorials may require specific software depending on the targeted industry. Common software used in 3D printing includes computer-aided design (CAD) software and slicing software to convert 3D models into printable files.

6. How can I find industry-specific 3D printing tutorials?

You can find industry-specific 3D printing tutorials through online platforms, industry forums, or by searching for specific tutorials on search engines. Additionally, manufacturers and industry associations often provide resources and tutorials on their websites.