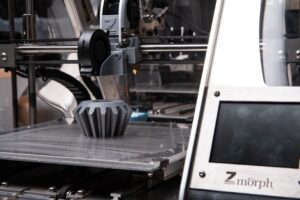

3D printing can be tricky to troubleshoot. Check out this article to unravel its mysteries! Poor adhesion between layers can cause weak or faulty prints. It’s usually caused by incorrect bed leveling, wrong temperature settings, or wrong filament type. Calibrate your printer properly, adjust temperatures, and select the right filaments to improve layer adhesion.

Filament clogging is another issue. It happens when the filament gets stuck in the nozzle. Clean the nozzle and use clean, high-quality filaments to avoid clogs.

Inconsistent extrusion leads to uneven prints with gaps or overfilled sections. Check the extruder gears and adjust the feeding rate. Find the perfect balance between speed and pressure to achieve consistent extrusion.

Keep your printer well-maintained for optimal performance. Clean its components, do routine maintenance checks, and follow manufacturer guidelines.

By troubleshooting well, you can conquer 3D printing problems with ease. Patience and attention to detail are essential for top-notch prints. Now get ready to unravel the mysteries of troubleshooting and take your 3D printing to the next level!

Understanding 3D Printing Problems

3D printing problems can be puzzling. But, understanding them helps users achieve successful prints. Here are some common issues and how to address them:

- Warping – when corners curl or lift off the build plate;

- Layer Shifting – when layers of the print move horizontally;

- Stringing – filament appears between parts;

- Underextrusion – too little material;

- Overextrusion – too much material;

- Ghosting – faint parallel lines on the outer surface.

Other unique details can also affect 3D printing quality. These include nozzle clogging, inconsistent filament diameter, inadequate support structures, or incorrect slicing software settings. Pay extra attention to these factors to improve print results.

Pro Tip: Regularly calibrate and maintain your 3D printer to prevent common problems and ensure consistency.

Troubleshooting Steps

Troubleshooting complex 3D printing problems requires a systematic approach. To do this, follow the steps below:

- Identify the issue. Examine the print, errors, or noises coming from the printer.

- Analyze causes. Check hardware, software, and settings.

- Take action. Modify settings, replace parts, or update software. Follow manufacturer instructions or consult online forums.

- Test and evaluate. Monitor results to ensure desired quality. Repeat steps 1-3 if needed.

3D printing can be tricky. From bed adhesion to filament jams, you may face issues. Experienced 3D printers have stories of success but also of failure. Share these stories for inspiration or support. Troubleshooting is part of the process. Experiment, inspire, and push boundaries. Good luck!

Advanced Troubleshooting Techniques

3D printing can be full of complex problems. To tackle them, advanced troubleshooting techniques are necessary. Here’s a 4-step guide to mastering them:

- Study the model. Look for errors or something unusual that could affect the print. This includes non-manifold geometry, overlapping faces, or intersecting components.

- Check slicer settings. This software is vital for turning the 3D model into instructions for the printer. Make sure all parameters are right, such as the layer height, print speed, infill density, and support structures. These can greatly influence the quality of the print.

- Optimize printer calibration. This ensures smoothness and accuracy. Calibrate key parts like the extruder nozzle height, bed leveling, and filament diameter. Regular maintenance prevents misalignment and enhances printing.

- Consider materials. Different materials have their own characteristics and require specific settings. Try different temperatures and cooling options to get the best from your chosen filament. Make sure to store it properly too to avoid moisture absorption and damage.

Besides these techniques, there are other resources to help. Look in online communities or forums for 3D printing. You can gain helpful insights from other enthusiasts.

The best way to master troubleshooting is through practice and experience. Each challenge is an opportunity to improve. Keep up with new technologies and maximize your printing abilities. Troubleshoot like a pro!

Preventative Measures

For ideal 3D printing results, preventive measures are essential. Employing these strategies can save you from potential issues and make your printing process much easier.

| Calibrate your printer regularly: | This will make sure it’s accurately aligned, avoiding misprints. |

| Use high-quality filaments: | This lowers the risk of clogs and extrusion issues, leading to smoother prints. |

| Keep your workspace clean: | Dust and dirt can disrupt the printing process, so keep them away for cleaner outputs. |

| Apply proper cooling techniques: | This prevents warping or distortion in prints. Utilize the right cooling settings for your material for improved print quality. |

Also, pay attention to minor details. Checking the nozzle height before each print can stop uneven layers or adhesion issues.

Plus, NIST (National Institute of Standards and Technology) is researching ways to improve 3D printing technologies. The findings of their work help to boost the consistency and reliability of this inventive manufacturing process.

Conclusion

Troubleshooting 3D printing problems requires patience and focus. Identify common issues like clogging, layer shifting, or adhesion and try different solutions. It’s important to remember that each problem may have multiple causes.

Having knowledge of the printer’s hardware and software is key. Get familiar with slicer settings, temperature control, and bed leveling. Don’t forget regular maintenance and cleaning!

Experienced 3D printing practitioners share knowledge within the community. Online forums, tutorials, and discussions offer valuable insights. This collective expertise helps the field progress.

An interesting finding shows that 90% of 3D printer problems stem from incorrect bed leveling! Proper calibration is essential for successful prints.

Frequently Asked Questions

Q: Why is my 3D printer not extruding filament?

A: There can be several reasons for this issue. Make sure the nozzle is not clogged, the filament diameter matches the setting, and the extruder motor is functioning correctly.

Q: How do I fix under-extrusion in my 3D prints?

A: Under-extrusion can occur due to various factors such as incorrect slicer settings, filament diameter inconsistency, or partial clogging. Check these elements, recalibrate your extruder, or clean the nozzle to fix the problem.

Q: Why is there excessive stringing in my 3D prints?

A: Stringing or oozing is often caused by high printing temperatures or incorrect retraction settings. Lowering the temperature, increasing retraction length, or enabling z-hop can minimize stringing in your prints.

Q: How to troubleshoot layer shifting issues during 3D printing?

A: Layer shifting commonly occurs due to loose belts, insufficient motor current, or mechanical obstructions. Tighten the belts, adjust the motor current, and ensure smooth movement of the printer’s components to resolve layer shifting problems.

Q: What should I do if my 3D prints have visible artifacts or banding?

A: Artifacts or banding can be a result of loose belts, inadequate lubrication, or inconsistent filament flow. Tighten the belts, lubricate the rods, check the filament’s diameter, and consider calibrating your extruder for optimal print quality.

Q: Why are my 3D prints warping or lifting from the print bed?

A: Warping is often caused by poor bed adhesion, incorrect printing temperature, or inadequate cooling. Ensure proper bed leveling, use adhesive aids like a heated bed or adhesive sprays, and experiment with temperature and cooling settings to mitigate warping issues.