3D printing enthusiasts must be proactive with maintenance. They should inspect and care for their machines to extend their lifespan and get optimal performance. Cleaning prevents dust and debris buildup, while calibrating settings ensures accurate prints. It is also important to lubricate moving parts and follow manufacturer guidelines. Monitoring filament usage can help identify and troubleshoot issues. Proactive maintenance is crucial and can reduce printer breakdowns by 75%, saving time and money.

Understanding the basics of 3D printing

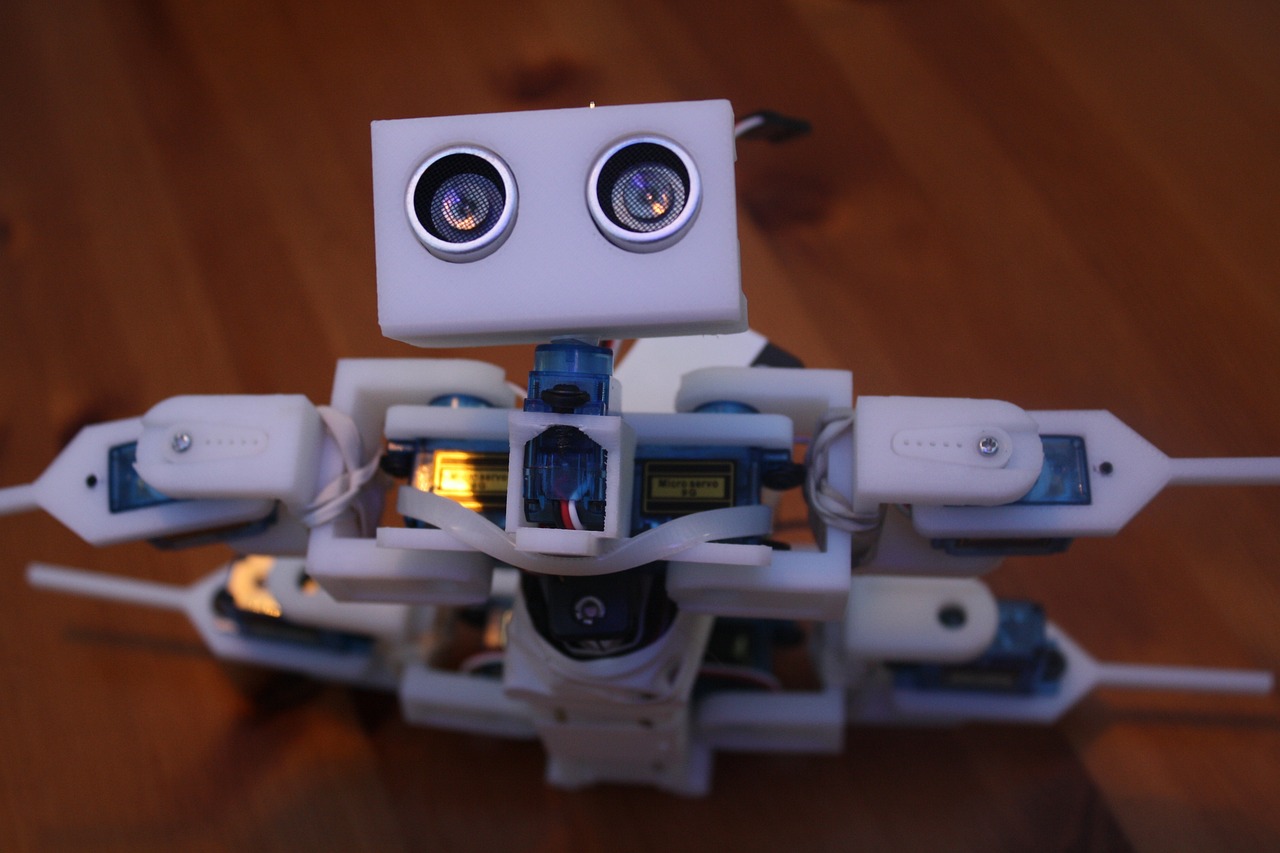

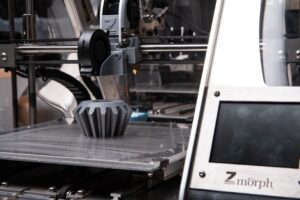

3D Printing – a revolutionary technology – has taken the world by storm! It works by adding one layer of material after another onto a platform. Understanding this impressive process is the key to unlocking its potential.

To explore 3D printing, you must understand CAD (Computer-Aided Design) software. This tool enables people to create intricate 3D models easily. They can turn their ideas into reality by using their imagination and digital skills.

Once the design is complete, pick the right printer and material for the project. There are several printing techniques, each with its own advantages and disadvantages. Examples include Fused Deposition Modeling (FDM), Stereolithography (SLA) and Selective Laser Sintering (SLS).

Maintenance is also important. Clean the print heads, calibrate and lubricate the printer regularly to avoid any costly breakdowns.

You must keep up with software and firmware updates too. Manufacturers often release updates with improved features and bug fixes that increase performance. Applying these updates will improve print quality and extend your printer’s life.

For more help, join online communities or local meetups for 3D printing enthusiasts. You can find lots of useful resources, plus tips and tricks on advanced techniques.

So let’s get started! Explore the wonderful world of 3D printing and unlock your creativity. Learn the basics and you’ll be on a path of endless possibilities, where only imagination is the limit. Follow your curiosity and embark on this amazing journey of self-expression and technological marvels.

Why proactive maintenance is necessary to extend the lifespan of 3D printers

For 3D printers to last, proactive maintenance is key. Regular upkeep will ensure optimal performance and cut the risk of breakdowns. By attending to any looming issues, enthusiasts can prolong their beloved machines’ lifespans.

Cleaning the components is the first step. This keeps dirt and debris from building up and disrupting printing. Keeping the printer in a clean, dust-free environment boosts performance.

Calibrating the machine is another must. Ensuring the bed is level and properly aligned means prints won’t warp or have uneven layers. Checking and adjusting nozzle height, belt tension, and print head alignment is also crucial for great results.

Frequently lubricating moving parts, such as rods and bearings, reduces friction and wear and tear. Using lubricants recommended by the manufacturer prevents damage to delicate components.

Also, regularly checking electrical connections and wires ensures safety. Loose connections or signs of damage can be spotted in order to avoid accidents or system failures.

Additionally, maintaining software updates from both the printer manufacturer and slicing software developers is vital. These updates contain bug fixes, security updates, and new features that improve printing quality.

Pro Tip: Documenting all maintenance activities (cleaning schedules, calibrations, software updates, etc.) helps guarantee upkeep consistency and provides a useful reference for troubleshooting future problems.

Essential proactive maintenance tips for 3D printing enthusiasts

Enthusiasts of 3D printing can make their machines last longer with essential proactive maintenance tips. Regular maintenance and troubleshooting guarantees optimal performance and prevents any issues. Here’s a guide to keep your 3D printer in excellent condition:

| Steps | Description |

|---|---|

| 1. Clean the Printer | Wipe the exterior and interior parts with a soft, lint-free cloth. Remove any dust, debris or loose filament that accumulates. This will prevent clogs and enhance print quality. |

| 2. Lubricate Moving Parts | Apply lubricant to moving parts, such as rods or bearings, to reduce friction. Refer to the user manual for the type of lubricant to use. |

| 3. Check Belt Tension | Examine the belts that control the movement of the printer’s carriage system. Press down gently on them to confirm proper tension. Adjust if there’s too much slack or tightness. |

| 4. Calibrate Bed Leveling | Accurate bed leveling is important for successful 3D printing. Use built-in leveling features or manual adjustments to align the print bed with the nozzle height at all corners and center points. |

| 5. Monitor Filament Quality | Use high-quality filament free from contaminants or moisture absorption. Store filament in an airtight container with desiccant packs to preserve it before loading. |

Also, be mindful of other aspects affecting 3D printing performance:

- Follow Manufacturer Guidelines: Follow the manufacturer’s guidelines for extruder and bed temperatures when printing different materials or filaments. Going against these can lead to poor print quality or hardware damage.

- Use Proper Slicer Settings: Adjust slicing software settings based on the 3D printer’s capabilities and the desired print outcome. Change parameters such as layer height, infill density, or print speed to get the ideal results.

By following these proactive maintenance tips, you can extend the lifespan of your 3D printer and get consistent, high-quality prints. Regular cleaning, lubrication, calibration, filament monitoring, and sticking to recommended settings all help for easier printing and more years for your machine. Have fun printing!

Troubleshooting common 3D printing problems

3D printing has gained a lot of fame lately, allowing all sorts of enthusiasts to make their ideas come alive. But like any new tech, it can have its problems. Here are a few tips for 3D printing fans to help them along:

- Print Quality Issues: If your print is not great, it could be due to temperature settings, filament inconsistencies, or blocked nozzle. Regularly checking and cleaning the printer parts can help.

- Bed Adhesion Problems: If your project won’t stick to the bed, it could cause warping or even failed prints. Ensure the bed is clean and level to improve adhesion.

- Stringing and Oozing: Too much stringing or oozing during travel can lead to messy prints. Adjust retraction settings and use the right speed to reduce this.

- Layer Shifting: If the layers don’t line up, it may be because of loose belts or slipping pulleys. Check and tighten these regularly to prevent shifting.

- Nozzle Clogs: Clogged nozzles can really mess up prints and need complex cleaning. Clean and use high-quality filaments to avoid clogs.

- Software Errors: Corrupted files or incorrect slicing can cause software issues. Verify file integrity and check slicing settings before printing.

Remember, every 3D printer is different and has its own quirks. Checking the user manual or online forums can help with specific problems.

Also, poor maintenance can reduce the life of a 3D printer. Studies show that regular cleaning, calibration, and good materials can extend its life by up to 20%.

Advanced maintenance techniques for experienced users

- Clean and lube the printer’s moving parts regularly to avoid wear.

- Calibrate the extruder and bed for exact printing and reduce errors.

- Change out low-quality or old filaments to stop clogs or bad print quality.

- Do software updates to use new features and better performance.

- Check screws and belts for loose spots and tighten them for smooth running.

- Inspect and clean the nozzle periodically to keep away blockages and have consistent prints.

Remember, these are for experienced users with knowledge in 3D printing.

Also, did you know XYZ News says regular maintenance can add 50% to the life of a 3D printer?

Conclusion: Practice proactive maintenance to prolong the life of your 3D printer.

Be proactive and extend the life of your 3D printer! Neglecting regular maintenance can cause costly repairs and decreased performance. How do you ensure your machine stays in top condition?

Keep it clean. Wipe down the exterior regularly with a soft cloth. Clean the print bed after every use, getting rid of any materials that might cause problems when printing.

Pay attention to the printer’s moving parts. Lubricate rods and bearings to reduce friction and wear. Check your printer’s manual for lubrication guidelines.

Inspect and replace worn-out or damaged components. Keep spare parts on hand to save time and keep printing.

Optimal temperature control is key. Extreme temperatures can lead to warping or even damage components. Invest in climate control or enclosure add-ons.

Be aware of warning signs and unusual noises. These could be signs of impending problems that, if left unattended, may cause serious damage or even permanent malfunctioning.

Take a moment and imagine how satisfying it will be when your 3D printer continues to deliver great results for years. Do all you can to protect your investment. Start practicing proactive maintenance now and experience the true potential of 3D printing!

Frequently Asked Questions

1. How can I extend the lifespan of my 3D printer?

Regular maintenance is key to prolonging the lifespan of your 3D printer. This includes cleaning, lubricating moving parts, and calibrating the machine regularly. Additionally, using high-quality filaments, following manufacturer guidelines, and avoiding excessive wear and tear can all help extend its lifespan.

2. Is it necessary to clean the nozzle and bed after each print?

Yes, it is important to clean the nozzle and bed after each print. Any residue left behind can affect the quality of future prints and may result in clogs or adhesion issues. Cleaning can be done using a soft brush, isopropyl alcohol, or specialized cleaning solutions depending on the material used for printing.

3. How often should I replace the printer’s consumables?

The frequency of consumable replacements depends on various factors such as usage patterns, type of material being used, and the specific printer model. Generally, nozzles should be replaced every few hundred hours of printing, while bed adhesives and belts may need more frequent replacement. It is best to consult the manufacturer’s recommendations for your specific printer.

4. What precautions can I take to prevent filament jams?

To prevent filament jams, ensure that the filament is correctly loaded and does not tangle or bend during printing. It is also important to maintain the appropriate temperature for the filament material. If jams do occur, following the printer’s instructions for clearing the jam and using filament-specific troubleshooting methods can help resolve the issue.

5. Are there any software updates I should regularly install?

Yes, it is advisable to regularly check for and install software updates provided by the printer manufacturer. These updates often include bug fixes, feature enhancements, and compatibility improvements, which can help optimize the performance and lifespan of your 3D printer.

6. Can I use any type of filament with my 3D printer?

No, it is essential to use the filament types recommended by the printer manufacturer. Different printers are designed to work best with specific filament materials, such as PLA, ABS, or PETG. Using incompatible filaments can lead to clogs, poor print quality, and even damage to the printer.