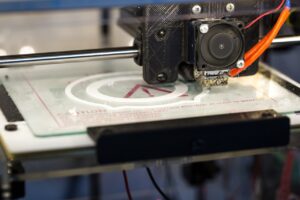

3D printing is a revolutionary tech that’s taken the world by storm. It has the power to create 3D objects layer by layer, shaking up multiple industries. Here, we’ll dive deep into advanced 3D printing techniques. We’ll give expert tutorials and tips to help you master this cutting-edge tech.

Let’s start with additive manufacturing. This process builds objects by adding material in layers. It allows intricate designs and complex geometries. When you understand the principles, you can be as creative as you want and make amazing 3D prints.

Multi-material 3D printing is fascinating. It lets you create objects with different materials at the same time. This opens up endless possibilities. You can combine rigid and flexible materials or add vibrant colors.

We can also integrate electronics into 3D printed objects. Thanks to conductive filaments and printable circuit boards, we can make functional devices with additive manufacturing. From embedded sensors to custom-made wearables, this tech offers a whole new dimension of innovation.

Did you know NASA has used 3D printing in space exploration? They produced a wrench on the International Space Station with a 3D printer from Made In Space Inc. This awesome feat shows the potential of advanced 3D printing techniques for future space missions.

Understanding Advanced 3D Printing Techniques

Advanced 3D printing techniques are key for pushing the boundaries of 3D manufacturing. With these methods, intricate and complex designs can be made with precision and efficiency. Let’s dive into this world and explore the techniques.

The following table shows various advanced 3D printing techniques:

| Technique | Description |

|---|---|

| Stereolithography | Uses UV lasers to solidify liquid resin layer-by-layer, creating highly detailed models |

| Selective Laser Sintering | Utilizes a high-powered laser to selectively fuse powdered materials, allowing for strong and durable prints |

| Digital Light Processing | Similar to stereolithography, uses a projector instead of a laser to cure liquid resin |

| Fused Deposition Modeling | Deposits successive layers of melted thermoplastic filament to create solid objects |

Various approaches are included in these advanced methods. Each technique has its own advantages, so users can choose the best one for their needs. It is important to comprehend the abilities and details of each technique to get the most out of 3D printing.

Pro Tip: When using advanced 3D printing techniques, make sure design files are optimized for manufacturing. Preparing the file properly and considering material properties can greatly improve the quality of your product.

Preparing for Advanced 3D Printing

To be successful in advanced 3D printing, meticulous planning and attention to detail are essential. Here’s a helpful guide to get you started!

| 1. Analyze the Design: | Take a close look at the design you’re using. Consider its measurements, details, and any special requirements for the printing process. |

| 2. Material Choice: | Choose the right material for your 3D printing. Think about its durability, flexibility, heat resistance, and compatibility with your design. Mix and match materials for new results. |

| 3. Printer Prep: | Keep your 3D printer clean and functioning. Make sure all parts are in working order and the printer bed is properly calibrated. |

| 4. Slicing & Structures: | Use slicing software to divide the design into printable layers. Put support structures in place for stability during printing. Aim for efficient placement for less post-processing work. |

| 5. Printing Environment: | Set up a suitable printing environment by controlling temperature, humidity, and ventilation. This helps achieve accurate prints without any deformation or warping. |

Also, adjust printer settings such as layer height, infill density, and print speed for the desired outcome. And don’t forget to document each step of the process.

Take inspiration from stories like an engineer who encountered many failures while experimenting with unusual designs, yet eventually found groundbreaking solutions that changed his field.

For innovative advanced 3D printing, push boundaries, embrace challenges, and always strive for improvement. With careful preparation and creative exploration, you can make remarkable achievements in this ever-evolving world!

Advanced 3D Printing Techniques

Advanced 3D printing techniques showcase remarkable possibilities. Selective Laser Sintering (SLS) fuses powdered materials together with a high-powered laser to create parts with accuracy. Stereolithography (SLA) uses photopolymerization to create objects layer by layer. Fused Deposition Modeling (FDM) builds objects by extruding thermoplastic materials. Digital Light Processing (DLP) cures liquid resin with a digital light projector. Electron Beam Melting (EBM) melts metal powders with electron beams for more complex components.

These techniques offer design freedom, faster production, cost efficiency, and better part performance. They’re used in industries such as aerospace, automotive, healthcare, and architecture. 3D printing has disrupted traditional supply chains and enabled customized products.

We’ve come a long way with 3D printing. From the first prototypes to today’s sophisticated systems, technology and materials have unlocked new opportunities. The future of 3D printing is exciting, with more innovation on the horizon.

Expert Tutorials and Tips

Elevate your 3D printing game with these tips! Calibrate your printer, choose the right filament material, optimize print settings, use support structures, and experiment with infill patterns. Don’t forget post-processing! Troubleshoot printing issues, master complex designs, and utilize slicing software.

Keep up with tech advancements and join online communities to stay ahead of the curve. Exchange ideas and push the boundaries of what is possible!

Conclusion

As our journey of exploring advanced 3D printing techniques comes to a close, it’s clear this field is ever-evolving and expanding. Throughout this article, experts provided various tutorials and tips, demonstrating there are innovative approaches to enhance 3D printing tech.

Multi-material printing was discussed extensively. By merging different materials in a single print, manufacturers can attain higher complexity and functionality. This unlocks new possibilities for intricate designs and functional prototypes.

Post-processing techniques have become significant. While 3D printers are becoming more advanced, desired surface finishes and textures can’t be achieved solely from the printing process. Sanding, polishing, and painting can significantly improve final appearance and aesthetics.

Throughout various industries, additive manufacturing technologies have made a revolution. According to MarketsandMarkets, the global 3D printing market size is predicted to reach $34.8 billion by 2026. Industries such as aerospace, automotive, healthcare, and consumer goods are driving this growth.

Frequently Asked Questions

FAQs: Advanced 3D Printing Techniques: Expert Tutorials and Tips

1. What are some advanced 3D printing techniques that experts use?

Experts often employ techniques such as DMLS (Direct Metal Laser Sintering), SLA (Stereolithography), and SLS (Selective Laser Sintering) to achieve intricate designs and high-quality prints in 3D printing.

2. How can I improve the surface finish of my 3D printed objects?

To enhance the surface finish, experts suggest using post-processing techniques like sanding, polishing, or applying a specialized finish such as epoxy resin or paint. Additionally, adjusting the print settings to minimize layer visibility can help improve the overall surface quality.

3. Can I 3D print flexible or rubber-like materials?

Absolutely! Advanced 3D printers support flexible filament materials like TPU (Thermoplastic Polyurethane) or TPE (Thermoplastic Elastomer) that allow you to create objects with different levels of flexibility and rubber-like textures.

4. How can I achieve multi-color or multi-material prints?

Experts recommend using either dual extruder 3D printers or the multi-material capabilities of certain advanced printers to achieve multi-color or multi-material prints. These printers allow you to use different filaments simultaneously, giving you more creative possibilities.

5. What are some essential tips for optimizing 3D print settings?

Experts suggest fine-tuning parameters such as layer height, print speed, infill density, and temperature to achieve the desired balance between print quality and speed. Additionally, ensuring proper bed leveling and using suitable support structures can greatly improve print success rates.

6. Can I print objects with movable parts using advanced 3D printing techniques?

Yes, with advanced 3D printing techniques, you can create objects with movable parts. This can be achieved through careful design considerations such as incorporating hinges, ball joints, or even printing in multiple parts that can be assembled.